Exploring Aluminum Structural Framing Benefits, Applications, and Innovations

Introduction to Aluminum Structural Framing

Aluminum structural framing has emerged as a cornerstone in modern construction and manufacturing, offering a blend of lightweight properties, strength, and versatility that traditional materials like steel struggle to match. As a specialist in this field, I can attest to the transformative impact aluminum has had across various sectors. Its ability to combine robustness with a significantly lower weight makes it an ideal choice for projects where reducing load is critical, such as in aerospace and automotive industries. This unique combination not only simplifies handling and installation but also contributes to lower transportation costs and improved energy efficiency.

The popularity of aluminum structural framing is further bolstered by its adaptability. Unlike steel, aluminum can be easily extruded into complex shapes, allowing for innovative design possibilities that cater to specific project needs. This flexibility is particularly advantageous in architectural applications where aesthetic considerations are paramount. Moreover, aluminum's inherent corrosion resistance, due to the formation of a protective oxide layer, ensures longevity and durability even in harsh environmental conditions, making it a preferred material for outdoor structures.

In addition to its physical attributes, aluminum structural framing supports sustainable practices. As a highly recyclable material, aluminum can be reused without losing its properties, aligning with the growing emphasis on environmental responsibility in construction practices. This aspect not only reduces the ecological footprint but also enhances the cost-effectiveness of using aluminum over its lifecycle. By choosing aluminum structural framing, industries can achieve a balance between performance, design flexibility, and sustainability, paving the way for innovative solutions in the 21st century.

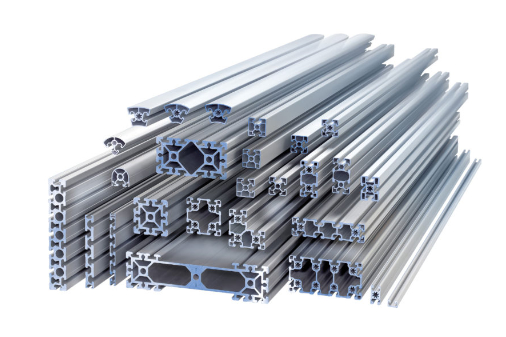

(Illustration of Aluminum Structural Framing)

Key Features and Advantages of Aluminum Structural Framing

Aluminum structural framing stands out in the world of construction and manufacturing due to its remarkable features and numerous advantages over traditional materials like steel. One of the most significant benefits of aluminum framing is its outstanding corrosion resistance. Unlike steel, which requires additional treatments to prevent rust, aluminum naturally forms a protective oxide layer that guards against corrosion. This makes it an ideal choice for outdoor applications and environments prone to moisture and harsh weather conditions, ensuring longevity and reduced maintenance costs over time.

Ease of Assembly and Adaptability

The ease of assembly is another key advantage of aluminum structural framing. Thanks to its lightweight nature, aluminum is easier to handle and install, reducing the need for heavy lifting equipment and minimizing the risk of manual handling injuries. This not only speeds up the construction process but also lowers labor costs. Moreover, aluminum's adaptability is unparalleled; it can be easily extruded into a variety of shapes and configurations, allowing for customized solutions that meet specific project requirements. This flexibility is particularly beneficial in industries such as aerospace and automotive, where precision and specialized designs are crucial.

Cost-Effectiveness and Environmental Benefits

When it comes to cost-effectiveness, aluminum structural framing offers significant advantages. Although the initial cost of aluminum might be higher than that of steel, the overall lifecycle cost is often lower. This is due to the reduced need for maintenance and the elimination of additional treatments to prevent corrosion. Furthermore, aluminum's lightweight nature leads to lower transportation costs, as it requires less energy to move and install. From an environmental perspective, aluminum is highly sustainable. It is infinitely recyclable without losing its properties, making it an eco-friendly choice that aligns with modern sustainability goals. In fact, nearly 75% of all aluminum ever produced is still in use today, underscoring its recyclability and contribution to reducing the ecological footprint.

In summary, the advantages of aluminum framing—ranging from its corrosion-resistant properties to its adaptability and cost-effectiveness—make it a superior choice for a wide range of applications. Its integration into various industries not only enhances performance but also supports sustainable practices, paving the way for future innovations. As we move forward, the next section will delve into the diverse applications of aluminum framing across different sectors, highlighting its versatility and impact in modern design and construction.

Common Applications of Aluminum Structural Framing in Industry

Aluminum structural framing has become a pivotal component across numerous industries, offering unparalleled benefits that drive innovation and efficiency. In my experience working with aluminum, I've seen firsthand how its unique properties cater to a wide range of applications, particularly in sectors like automotive, aerospace, and construction.

(Applications In Automotive Industry, Aerospace Sector and Architecture)

(Applications In Automotive Industry, Aerospace Sector and Architecture)

Automotive Industry

In the automotive sector, the demand for lightweight and fuel-efficient vehicles has propelled the use of aluminum framing. Its high strength-to-weight ratio makes it an excellent choice for reducing vehicle weight without compromising safety or performance. This not only improves fuel efficiency but also aligns with stringent environmental regulations aimed at reducing emissions. The versatility of aluminum allows for the creation of complex shapes and structures, supporting both functional and aesthetic automotive designs. As noted in industry resources, aluminum's role in enhancing fuel economy and safety is a testament to its indispensability in modern vehicle manufacturing (source).

Aerospace Sector

Similarly, the aerospace industry capitalizes on aluminum's lightweight properties to improve aircraft performance. The ability to reduce weight translates to better fuel consumption and increased payload capacity, which are critical factors in aviation. Aluminum's natural resistance to corrosion further ensures that aircraft components remain durable and reliable, even in the demanding conditions experienced at high altitudes. The use of modular aluminum structures enables aerospace engineers to design ergonomic and efficient aircraft interiors, enhancing passenger comfort and safety.

Construction and Architecture

In the realm of construction, aluminum framing is celebrated for its adaptability and aesthetic appeal. Architects and builders leverage its flexibility to create modular structures that are not only functional but also visually striking. The ease of assembly and customization allows for innovative architectural designs that meet specific client needs. Additionally, aluminum's durability and low maintenance requirements make it a cost-effective choice for both residential and commercial projects. As a recyclable material, it also supports sustainable building practices, contributing to the growing trend of green construction.

Aluminum structural framing's extensive applications across various industries highlight its versatility and effectiveness in meeting modern engineering and design challenges. As we continue to explore its potential, the next section will delve into recent innovations in aluminum framing systems, showcasing how advancements in technology are enhancing its performance and expanding its uses.

Innovations in Aluminum Framing Systems

In the ever-evolving landscape of construction and manufacturing, aluminum framing systems are at the forefront of innovation, offering groundbreaking advancements that significantly enhance their performance and efficiency. At Sunmay Aluminium, we have witnessed firsthand the transformative impact of these innovations, particularly in new extrusion techniques and design improvements that have redefined the possibilities of aluminum structural framing.

Advancements in Extrusion Techniques

Extrusion technology has seen remarkable advancements, enabling the creation of more complex and precise aluminum profiles. The integration of Computer Numerical Control (CNC) machining has revolutionized the process, allowing for real-time adjustments and ensuring components meet exact specifications. This precision reduces the need for additional machining, saving time and resources while enhancing the overall quality of aluminum structures (source).

Moreover, the development of nano-coatings applied to extruded aluminum surfaces has improved durability and functionality. These coatings repel water, oil, and dirt, preventing corrosion and enhancing the aesthetic appearance of components. Such innovations are particularly beneficial in architectural applications where long-term protection and easy maintenance are desired.

Design Improvements and Efficiency

Design improvements in aluminum framing systems have also led to increased efficiency and adaptability. Modern extrusion techniques allow for the incorporation of features such as flanges, grooves, and internal cavities directly into the profiles, eliminating the need for additional machining operations. This design flexibility supports innovative solutions and customization to meet specific application requirements, whether in aerospace, automotive, or construction sectors.

Furthermore, the integration of the Internet of Things (IoT) and data analytics into the extrusion process has optimized production, reduced waste, and improved product quality. By collecting real-time data on key process parameters, manufacturers can make informed adjustments to enhance performance, minimize downtime, and maximize productivity.

As we continue to explore the potential of aluminum framing systems, these innovations provide a glimpse into a future where enhanced precision, sustainability, and design flexibility are the norms. The next section will compare T-slot aluminum framing with other framing systems, highlighting the unique advantages and considerations of each option.

Comparing T-Slot and Other Aluminum Framing Systems

As we delve into the realm of aluminum framing systems, the T-slot aluminum framing emerges as a staple in modular design, favored for its versatility and ease of assembly. At Sunmay Aluminium, we have extensive experience with T-slot systems, which are renowned for their ability to create modular structures that are both functional and adaptable. The T-slot design allows for easy assembly and reconfiguration, making it ideal for projects that require frequent adjustments or expansions.

(T-Slot Aluminum Framing)

Advantages of T-Slot Aluminum Framing

The primary advantage of T-slot aluminum framing lies in its flexibility. The T-slot design permits the addition of accessories and components without the need for drilling or welding, thus preserving the integrity of the structure. This feature is particularly beneficial in industrial settings where modifications are frequent. Furthermore, T-slot systems are compatible with a wide range of profiles and connectors, allowing for extensive customization to meet specific project requirements. The ease of assembly and disassembly also translates to reduced labor costs and time savings, making it a cost-effective solution for many applications.

Limitations and Alternatives

Despite its advantages, T-slot aluminum framing is not without its limitations. The reliance on friction to maintain alignment can lead to issues in high-vibration environments, where joints may loosen over time. This is where alternatives like the AngleLock system come into play. As highlighted in recent studies, AngleLock offers enhanced joint stability through a mechanical lock system that eliminates pivot points, providing superior strength and durability (source).

AngleLock's unique self-aligning brackets and angled bolts ensure a rigid connection that withstands dynamic loads, making it suitable for demanding applications. However, the availability of AngleLock components is more limited compared to the widely accessible T-slot profiles, which can be a consideration for projects requiring rapid deployment or specific customizations.

Why T-Slot Remains a Popular Choice

Despite the emergence of alternatives, T-slot aluminum framing remains a popular choice due to its proven track record and extensive compatibility with existing systems. The ability to easily integrate with other modular components and the availability of a vast library of profiles make it a go-to option for many engineers and designers. Additionally, the widespread distribution network ensures that T-slot components are readily available, reducing lead times and facilitating project execution.

In conclusion, while T-slot aluminum framing offers unparalleled flexibility and ease of use, it's essential to consider the specific needs of your project when choosing a framing system. As we explore further, the next section will provide guidance on selecting the appropriate aluminum framing system, taking into account factors such as load requirements, environmental conditions, and budget constraints.

Choosing the Right Aluminum Framing for Your Project

Selecting the appropriate aluminum framing system for your project is crucial to ensure both functionality and efficiency. At Sunmay Aluminium, we understand that each project comes with its unique set of requirements and challenges. Therefore, it is essential to consider several critical factors when choosing the right aluminum framing system.

Assessing Load Requirements

The first step in choosing aluminum framing is to evaluate the load requirements of your project. This involves understanding the weight that the structure will need to support, which can vary significantly depending on the application. For instance, a framing system used in an automotive assembly line might require higher load-bearing capabilities compared to a lightweight architectural installation. Ensuring that the framing system can handle the intended load is vital to maintaining structural integrity and safety.

Considering Environmental Conditions

Environmental conditions play a significant role in determining the suitability of an aluminum framing system. If the project is located in an area with high humidity or exposure to corrosive elements, opting for corrosion-resistant aluminum is advisable. Aluminum's natural oxide layer offers excellent protection against corrosion, but additional coatings or treatments can enhance its durability in harsh environments. Additionally, consider the thermal expansion properties of aluminum, especially for outdoor applications where temperature fluctuations are common.

Budget Constraints and Cost-Effectiveness

Budget constraints are another crucial factor when selecting an aluminum framing system. While aluminum framing may have a higher upfront cost compared to other materials, its long-term benefits often justify the investment. The lightweight nature of aluminum reduces transportation and installation costs, and its recyclability contributes to potential savings in material disposal. Moreover, the modular design of aluminum framing allows for easy modifications and expansions, providing flexibility and cost-effectiveness over the project's lifecycle.

To make an informed decision, it's essential to weigh these factors against the specific needs of your project. Collaborating with experienced suppliers and manufacturers can also provide valuable insights and customized solutions tailored to your requirements. As we move forward, the next section will conclude our exploration of aluminum structural framing by summarizing its benefits and discussing future trends that could shape the industry.

Conclusion and Future Trends in Aluminum Structural Framing

As we conclude our exploration of aluminum structural framing, it is evident that this material offers a multitude of benefits that make it a preferred choice across various industries. Its lightweight nature, coupled with exceptional strength and corrosion resistance, provides a versatile solution for modern construction and manufacturing challenges. Aluminum's adaptability allows for innovative designs, while its recyclability aligns with sustainable practices, making it an eco-friendly option for future projects.

Looking ahead, the future of aluminum framing is poised to embrace several exciting trends and innovations. As sustainability becomes a central focus in construction, aluminum's inherent properties will continue to drive its popularity. Advanced thermal breaks and energy-efficient glazing are expected to enhance the energy performance of aluminum structures, reducing overall carbon footprints. Additionally, the integration of smart technologies and the Internet of Things (IoT) will enable aluminum framing systems to contribute significantly to smart city initiatives, optimizing energy usage and enhancing urban living environments.

Technological advancements are also set to redefine the landscape of aluminum framing. New extrusion techniques and design improvements will allow for even more complex and precise profiles, pushing the boundaries of what is possible in architectural and industrial applications. Building Information Modeling (BIM) and data analytics will further streamline design and construction processes, ensuring precision and efficiency from concept to completion.

At Sunmay Aluminium, we are committed to staying at the forefront of these innovations, continually optimizing our processes to deliver superior aluminum solutions. Our dedication to quality and sustainability positions us as a leader in the industry, ready to meet the evolving needs of our clients worldwide. As we look to the future, we encourage you to explore the potential of aluminum structural framing for your next project, leveraging its myriad benefits to achieve innovative and sustainable outcomes.

FAQs on Aluminum Structural Framing

1. How strong is aluminum framing?

Aluminum framing offers a strength of up to 35,000 psi, comparable to steel, making it a reliable choice for various structural applications.

2. What are the benefits of aluminum framing?

Aluminum framing is lightweight, corrosion-resistant, eco-friendly, and allows for complex design flexibility, making it ideal for diverse applications.

3. Can you frame a house with aluminum?

Yes, aluminum framing can be used in house construction, offering strength comparable to steel and enhanced protection against environmental elements.

4. Why is the T-slot system popular in aluminum framing?

T-slot systems are favored for their modular design, easy assembly, and adaptability, allowing for quick modifications without drilling or welding.

5. What industries benefit the most from aluminum structural framing?

Industries like automotive, aerospace, and construction benefit from aluminum framing due to its lightweight nature, strength, and design versatility.